Adversity Brings Opportunity in the Form of...Strawberry Sorbet?

I'm sure some sage has written wise words correlating adversity with opportunity and growth. And you would be well within your rights to ask why I'm bringing this up in a post that's ostensibly a recipe for strawberry sorbet, and the answer is this: When Dave developed lactose intolerance in his early 40s we were devastated. As I wrote at the time:

It was a very bad day. One of those days that forever changes you. A day that delineates a definite "Before" and "After." The life-altering occurrence? My husband found out he was lactose intolerant. And, no, not just the "take a Lactaid pill and have some cheesecake anyway" kind of lactose intolerant, but the kind where it's inadvisable to partake of butter, fresh cheeses or any product containing milk without risking...ahem...shall we say "explosive repercussions."

As Joni Mitchell wrote: "You don't know what you've got till it's gone."

It led to a complete rethinking of our very profligate and, frankly, thoughtless use of dairy in everything from our morning toast to creamy casseroles to buttery pastries and desserts. Store shelves today proudly proclaim their products to be "dairy free" and "vegan," with lactose-free butter, milk and cheeses in stock almost everywhere. Even restaurant menus now offer dairy-free options and label entrées "DF" or "V," but thirty years ago it meant switching to margarine and tofu-based simulacra of our beloved dairy products.

It led to a complete rethinking of our very profligate and, frankly, thoughtless use of dairy in everything from our morning toast to creamy casseroles to buttery pastries and desserts. Store shelves today proudly proclaim their products to be "dairy free" and "vegan," with lactose-free butter, milk and cheeses in stock almost everywhere. Even restaurant menus now offer dairy-free options and label entrées "DF" or "V," but thirty years ago it meant switching to margarine and tofu-based simulacra of our beloved dairy products.

And you could pretty much rule out a romantic date night—the machinations involved in trying to ascertain what was and wasn't available, the wait staffs' eyes rolling around their heads and a whimper of "I'll have to check with the kitchen" uttered in complete helplessness, then ordering something and hoping desperately they'd got it right made for a less-than-relaxing experience.

But the upsides were legion, as well. One of the big reasons for Dave's dive into sourdough—yes, it predated the nation's "discovery" of this ancient technique during COVID, particularly by middle-aged white men—was because reading paragraph-long bread labels on shopping trips was taking way too long and the "may have been produced in a facility using dairy" descriptions felt too risky. I could also list benefits like discovering the infinite and delicious permutations of olive oil cakes, and the concomitant escalation in our use of (organic) olive oil, or, to get back to the point of this post, the discovery of fresh sorbets that were like the creamier, less icy Italian versions our Cuisinart ice cream maker produces.

With local fruit season just beginning to burst onto the scene, you can count on several berry and stone fruit sorbets appearing as luscious cappers to backyard soirées around here. This strawberry version is easy, taking less than an hour to pop into freezer and then three or four hours to freeze.

With local fruit season just beginning to burst onto the scene, you can count on several berry and stone fruit sorbets appearing as luscious cappers to backyard soirées around here. This strawberry version is easy, taking less than an hour to pop into freezer and then three or four hours to freeze.

Fresh Strawberry Sorbet

2 pints fresh strawberries

1 1/4 cups simple syrup (equal parts sugar and water, warmed and stirred until sugar is completely dissolved)

2 Tbsp. fresh-squeezed orange juice or a teaspoon or two of triple sec or Cointreau (optional)

Cool the simple syrup in the refrigerator.

Put the rinsed, stemmed and halved strawberries into a food processor or blender with a quarter cup of the simple syrup and blend until smooth. Pour the mixture into a larger bowl. Mix in the rest of the simple syrup (or to taste). Mix in the orange juice or booze, if using. Pour into an ice cream/sorbet machine and follow manufacturer’s directions. Freeze for a few hours before serving.

Photo of blue bowl and hydrangeas by Denise della Santina.

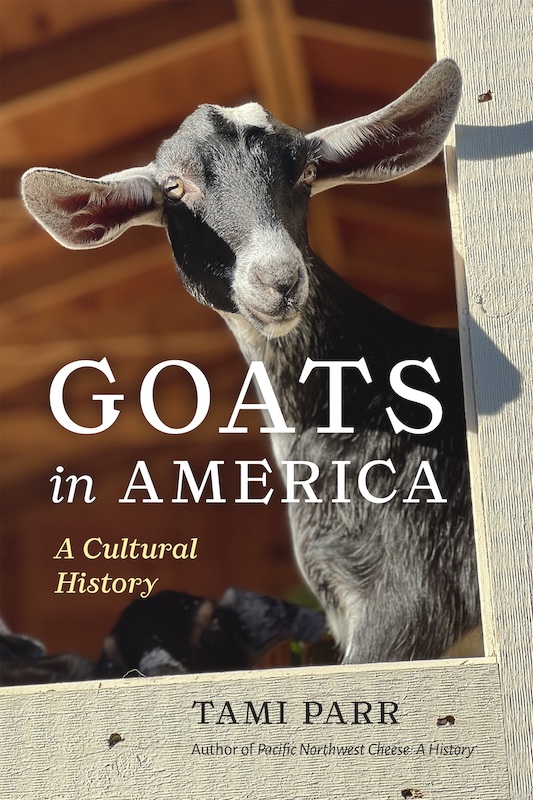

Parr: This book grew out of my involvement in the cheese world. While writing my previous two books (and the blog before that) I spent a lot of time hanging around cheesemakers and visiting farms around the Pacific Northwest.

Parr: This book grew out of my involvement in the cheese world. While writing my previous two books (and the blog before that) I spent a lot of time hanging around cheesemakers and visiting farms around the Pacific Northwest.

Plus, if you make it in the summer and get too warm standing in front of the stove, you are allowed a glass (or more, depending on how quickly you drain it) of a chilled white or rosé.

Plus, if you make it in the summer and get too warm standing in front of the stove, you are allowed a glass (or more, depending on how quickly you drain it) of a chilled white or rosé.

Above is his second harvest of fava beans. He shared some of the first picking, which I added to a salad under a gorgeous filet of grilled salmon, then he asked if I could help out with this second massive haul. My answer was something akin to "Hell yes!" and I rushed over with bag in hand, coming home with at least five pounds of pods.

Above is his second harvest of fava beans. He shared some of the first picking, which I added to a salad under a gorgeous filet of grilled salmon, then he asked if I could help out with this second massive haul. My answer was something akin to "Hell yes!" and I rushed over with bag in hand, coming home with at least five pounds of pods.